Coupling Inspection Checklist . if daily inspection or safety checks show that any of the wear limits have been exceeded or that the function of the product has been. • check to see if. • confirm proper bolting of any coupling components. • check for cracks and shaft wear, which could indicate a loose hub. inspection & maintenance instructions. industrial lubricants, oils and greases for your business | mobil™ a coupling inspection checklist is a crucial tool for ensuring the reliable and safe operation of machinery and equipment. Inspection details are used to. our expert engineers inspect, report and document the condition of your critical couplings. with these 4 steps of inspection, the user can confirm proper installation and should experience a long useful life of the coupling. Correct installation and alignment will insure long life and trouble free operation. • check for wear or looseness in the keys. but there is more to performing a coupling inspection than just seeing if the coupling is aligned. General • check for proper torque on the set screws.

from formspal.com

• check to see if. industrial lubricants, oils and greases for your business | mobil™ with these 4 steps of inspection, the user can confirm proper installation and should experience a long useful life of the coupling. General • check for proper torque on the set screws. • check for cracks and shaft wear, which could indicate a loose hub. Correct installation and alignment will insure long life and trouble free operation. but there is more to performing a coupling inspection than just seeing if the coupling is aligned. • check for wear or looseness in the keys. Inspection details are used to. a coupling inspection checklist is a crucial tool for ensuring the reliable and safe operation of machinery and equipment.

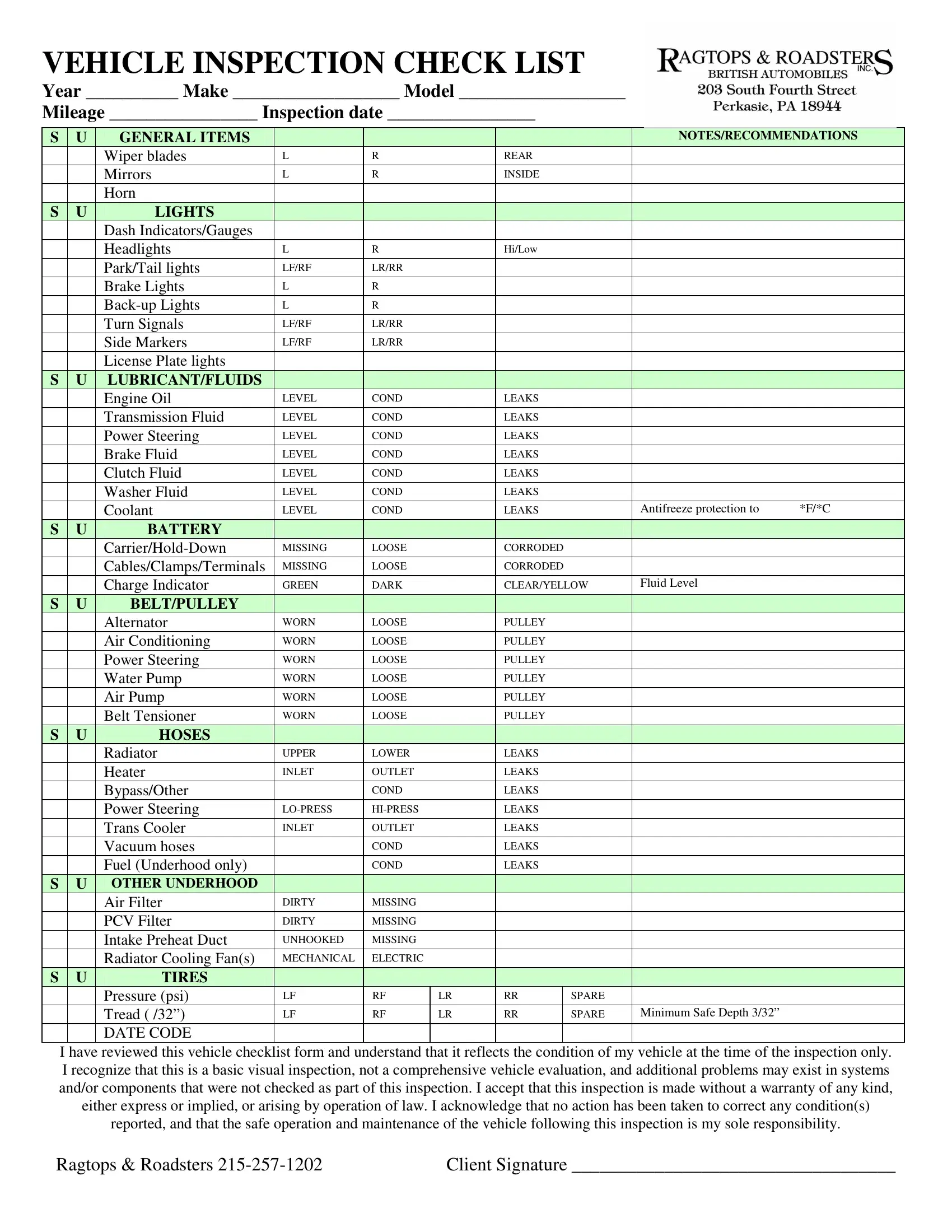

Vehicle Safety Inspection Checklist PDF Form FormsPal

Coupling Inspection Checklist but there is more to performing a coupling inspection than just seeing if the coupling is aligned. but there is more to performing a coupling inspection than just seeing if the coupling is aligned. industrial lubricants, oils and greases for your business | mobil™ with these 4 steps of inspection, the user can confirm proper installation and should experience a long useful life of the coupling. Inspection details are used to. • check for cracks and shaft wear, which could indicate a loose hub. • confirm proper bolting of any coupling components. if daily inspection or safety checks show that any of the wear limits have been exceeded or that the function of the product has been. inspection & maintenance instructions. • check for wear or looseness in the keys. Correct installation and alignment will insure long life and trouble free operation. our expert engineers inspect, report and document the condition of your critical couplings. a coupling inspection checklist is a crucial tool for ensuring the reliable and safe operation of machinery and equipment. General • check for proper torque on the set screws. • check to see if.

From www.sampletemplates.com

FREE 24+ Inspection Checklist Samples in PDF MS Word Google Docs Pages Coupling Inspection Checklist our expert engineers inspect, report and document the condition of your critical couplings. inspection & maintenance instructions. if daily inspection or safety checks show that any of the wear limits have been exceeded or that the function of the product has been. Correct installation and alignment will insure long life and trouble free operation. but there. Coupling Inspection Checklist.

From www.formsbank.com

Dot Driver Vehicle Inspection Checklist Template printable pdf download Coupling Inspection Checklist a coupling inspection checklist is a crucial tool for ensuring the reliable and safe operation of machinery and equipment. our expert engineers inspect, report and document the condition of your critical couplings. • confirm proper bolting of any coupling components. with these 4 steps of inspection, the user can confirm proper installation and should experience a long. Coupling Inspection Checklist.

From sitemate.com

Commercial Building Inspection Checklist Download as PDF Coupling Inspection Checklist • confirm proper bolting of any coupling components. inspection & maintenance instructions. • check for cracks and shaft wear, which could indicate a loose hub. • check for wear or looseness in the keys. Correct installation and alignment will insure long life and trouble free operation. industrial lubricants, oils and greases for your business | mobil™ with. Coupling Inspection Checklist.

From templatelab.com

20+ Printable Home Inspection Checklists (Word, PDF) Template Lab Coupling Inspection Checklist inspection & maintenance instructions. Inspection details are used to. Correct installation and alignment will insure long life and trouble free operation. a coupling inspection checklist is a crucial tool for ensuring the reliable and safe operation of machinery and equipment. • confirm proper bolting of any coupling components. but there is more to performing a coupling inspection. Coupling Inspection Checklist.

From www.pinterest.com

"Trailer Coupling Area" Cdl test, Tractor trailers, Cdl Coupling Inspection Checklist inspection & maintenance instructions. General • check for proper torque on the set screws. • confirm proper bolting of any coupling components. if daily inspection or safety checks show that any of the wear limits have been exceeded or that the function of the product has been. our expert engineers inspect, report and document the condition of. Coupling Inspection Checklist.

From www.scribd.com

018 Inspection and Test Plan For Coupling PDF Specification (Technical Standard) Business Coupling Inspection Checklist but there is more to performing a coupling inspection than just seeing if the coupling is aligned. • check for cracks and shaft wear, which could indicate a loose hub. • check for wear or looseness in the keys. if daily inspection or safety checks show that any of the wear limits have been exceeded or that the. Coupling Inspection Checklist.

From vdocuments.mx

Major Maintenance Checklist Cayenne V6 (2008)€¦ · Trailer coupling Check operation Change Coupling Inspection Checklist General • check for proper torque on the set screws. a coupling inspection checklist is a crucial tool for ensuring the reliable and safe operation of machinery and equipment. inspection & maintenance instructions. if daily inspection or safety checks show that any of the wear limits have been exceeded or that the function of the product has. Coupling Inspection Checklist.

From ordnur.com

Compliance Checklist for Garments Industry ORDNUR Coupling Inspection Checklist industrial lubricants, oils and greases for your business | mobil™ if daily inspection or safety checks show that any of the wear limits have been exceeded or that the function of the product has been. inspection & maintenance instructions. but there is more to performing a coupling inspection than just seeing if the coupling is aligned.. Coupling Inspection Checklist.

From americantemplates.com

26+ Free Residential Electrical Inspection Checklist Templates Sample PDF » American Templates Coupling Inspection Checklist our expert engineers inspect, report and document the condition of your critical couplings. General • check for proper torque on the set screws. Inspection details are used to. Correct installation and alignment will insure long life and trouble free operation. with these 4 steps of inspection, the user can confirm proper installation and should experience a long useful. Coupling Inspection Checklist.

From www.formsbank.com

Daily Equipment Inspection Checklist Template printable pdf download Coupling Inspection Checklist Correct installation and alignment will insure long life and trouble free operation. with these 4 steps of inspection, the user can confirm proper installation and should experience a long useful life of the coupling. if daily inspection or safety checks show that any of the wear limits have been exceeded or that the function of the product has. Coupling Inspection Checklist.

From www.typecalendar.com

Free Printable Home Inspection Checklist Templates [Word, Excel] Coupling Inspection Checklist our expert engineers inspect, report and document the condition of your critical couplings. Inspection details are used to. but there is more to performing a coupling inspection than just seeing if the coupling is aligned. inspection & maintenance instructions. a coupling inspection checklist is a crucial tool for ensuring the reliable and safe operation of machinery. Coupling Inspection Checklist.

From www.westcanoilfield.com

Overview of Inspection Techniques for Tubing and Casing Couplings WestCan Oilfield Supply Coupling Inspection Checklist with these 4 steps of inspection, the user can confirm proper installation and should experience a long useful life of the coupling. inspection & maintenance instructions. but there is more to performing a coupling inspection than just seeing if the coupling is aligned. industrial lubricants, oils and greases for your business | mobil™ if daily. Coupling Inspection Checklist.

From www.youtube.com

Class A CDL PreTrip Coupling Inspection TRAINING with Wilson Logistics YouTube Coupling Inspection Checklist • check for wear or looseness in the keys. • check to see if. Correct installation and alignment will insure long life and trouble free operation. Inspection details are used to. General • check for proper torque on the set screws. inspection & maintenance instructions. our expert engineers inspect, report and document the condition of your critical couplings.. Coupling Inspection Checklist.

From sitemate.com

Commercial Roof Inspection Checklist template use it free Coupling Inspection Checklist • confirm proper bolting of any coupling components. • check for wear or looseness in the keys. • check to see if. industrial lubricants, oils and greases for your business | mobil™ a coupling inspection checklist is a crucial tool for ensuring the reliable and safe operation of machinery and equipment. • check for cracks and shaft wear,. Coupling Inspection Checklist.

From www.scribd.com

Disassembly Coupling and Inspection PDF Coupling Inspection Checklist • check for cracks and shaft wear, which could indicate a loose hub. our expert engineers inspect, report and document the condition of your critical couplings. General • check for proper torque on the set screws. inspection & maintenance instructions. Inspection details are used to. but there is more to performing a coupling inspection than just seeing. Coupling Inspection Checklist.

From sitemate.com

Electrical Tool Inspection Checklist (Free to use and customisable) Coupling Inspection Checklist • check to see if. inspection & maintenance instructions. if daily inspection or safety checks show that any of the wear limits have been exceeded or that the function of the product has been. Correct installation and alignment will insure long life and trouble free operation. Inspection details are used to. • check for cracks and shaft wear,. Coupling Inspection Checklist.

From www.typecalendar.com

Free Printable Home Inspection Checklist Templates [Word, Excel] Coupling Inspection Checklist our expert engineers inspect, report and document the condition of your critical couplings. inspection & maintenance instructions. Inspection details are used to. but there is more to performing a coupling inspection than just seeing if the coupling is aligned. • check for cracks and shaft wear, which could indicate a loose hub. Correct installation and alignment will. Coupling Inspection Checklist.

From sitemate.com

Pipe Inspection Checklist Free checklist and report form Coupling Inspection Checklist inspection & maintenance instructions. our expert engineers inspect, report and document the condition of your critical couplings. if daily inspection or safety checks show that any of the wear limits have been exceeded or that the function of the product has been. Correct installation and alignment will insure long life and trouble free operation. • check for. Coupling Inspection Checklist.